1. About Dry-Type Transformers

Dry-type transformers refer to transformers in which cores and windings are not immersed in insulating oil. There are two cooling methods for dry-type transformers: natural air cooling (AN) and forced air cooling (PF). There are two structural types of dry-type transformers: solid-cast insulation (SCB type) and non-encapsulated winding structures. From the relative positions of the high and low voltage windings, there are concentric and interleaved types. The concentric structure is simple and convenient to manufacture, and most dry-type transformers adopt this structure. The interleaved type is mainly used in the manufacture of specialty transformers.

2. Specifications of Dry-Type Transformers

Taking the SCB-11—1250KVA/10KV/0.4KV dry-type transformer as an example to explain the meaning of model specifications: In the above model specifications, S represents a three-phase power transformer, C indicates that the transformer winding is a resin-poured solid, the letter G in position C indicates the external insulation medium of the winding is air, B is for cast winding, and R in position B represents wrapped winding, 11 is the series number, 1250KVA is the rated capacity of the transformer, 10KV is the rated voltage of the primary side of the transformer, and 0.4KV is the rated voltage on the secondary side of the transformer.

3. Technical Parameters of Dry-Type Transformers

The technical parameters of dry-type transformers include:

– Frequency: 50Hz

– No-load loss: less than 4%

– Low-voltage withstand strength: 2KV/min without breakdown

– Insulation resistance on the low-voltage side not less than 2MΩ

– Winding connection: /Y/yn0, and D/yn0

– Coil allowable temperature rise: 100K

– Cooling method: natural air cooling or temperature-controlled air cooling

– Noise factor: less than 30dB

Table 1 shows the loss parameters of various capacity dry-type transformers (SCB type).

4. Operating Environment Requirements for Dry-Type Transformers

The operating environment requirements for dry-type transformers are as follows:

– Ambient temperature: -10 to 45°C

– Relative humidity of air: daily average not more than 95%, monthly average not more than 90%

– Altitude below 1600 meters (under rated capacity)

5. Advantages and Disadvantages of Dry-Type and Oil-Immersed Transformers

In terms of cost, dry-type transformers are more expensive than oil-immersed transformers. Oil-immersed transformers can have larger capacities compared to dry-type transformers. Dry-type transformers are used in underground layers, floors, and crowded places. Oil-immersed transformers are used in standalone substations. Box-type substations generally use dry-type transformers. Oil-immersed transformers are used in places with large spaces, while dry-type transformers are used in narrow spaces. In regions with humid climate conditions, oil-immersed transformers are used. Dry-type transformers are used in places requiring “fire and explosion proofing”. The load-bearing capacity of dry-type transformers is inferior to that of oil-immersed transformers. Dry-type transformers should operate at rated capacity, whereas oil-immersed transformers can withstand short-term overloads.

6. Differences Between SCB Type Dry-Type Transformers and SGB Type Transformers

In winding coils: Low-voltage coils of SCB type dry-type transformers use foil winding. Winding structure: single-layer winding with copper foil, interlayer material contains latent curing agents of epoxy resin and inferior composite foil. Winding material: uses highly conductive oxygen-free copper, with a copper content of 99.99%. SGB type dry-type transformers use wire winding for low voltage coils. Winding structure: cylindrical coils, with many common glass fiber-covered flat copper wires.

SGB type dry-type transformers have a stronger short-circuit resistance than SCB type dry-type transformers.

In terms of cooling, SCB type dry-type transformers perform better than SGB type transformers.

In terms of load loss, SCB type dry-type transformers have lower losses than SGB type dry-type transformers.

In terms of temperature rise, SCB type has better cooling than SGB type.

7. Price Comparison of SGB, SCB, S13 Type Power Transformers

Taking power transformers with a rated capacity of 1250KVA as an example, compare the quotes from the same type of manufacturers online.

The quotes for SGB11—1250KVA/10KV/0.4KV, SCB11—1250KVA/10KV/0.4KV, S13—1250KVA/10KV/0.4KV power transformers were respectively 93800 yuan/unit, 95600 yuan/unit, and 59600 yuan/unit. From this, it can be seen that the price difference between SCB and SGB types is not significant, and dry-type transformers cost about 1.5 times more than oil-immersed transformers.

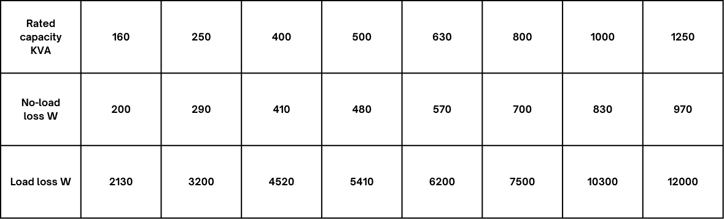

8. Loss Parameters of S13 Type Oil-Immersed Power Transformers

The loss parameters of the S13 type oil-immersed power transformers are shown in Table 2.

From Tables 1 and 2, it can be seen that the no-load loss of dry-type transformers are greater than those of oil-immersed transformers. However, the load loss of dry-type transformers are less than that of oil-immersed transformers.

9. Guidelines for Choosing Power Transformers

When choosing transformers, please refer to GB/T17468—2008 “The Guide for Choice Power Transformers” and GB4208—-2008 “Degrees of Protection Provided by Enclosures (IP Code)”, and select power transformers suitable for the environmental requirements of the site. The general principles of transformer selection: When selecting technical parameters of transformers, the overall reliability of the transformer should be the basis, taking into account the technical parameters’ advancement and reasonableness, economy, combined with the operating mode, and proposing technical and economic indicators. In addition, possible impacts on system safety operation, environmental protection, material saving, transportation, and installation space have to be considered.

10. Example of Selecting Power Transformers

A new cold-rolled strip steel plant on an industrial platform originally designed three transformers (two 1250KVA transformers and one 400KVA transformer) using SCB type dry-type transformers. The supervisor of the owner’s unit consulted us about the prices of these three transformers. Based on the site, environment, and loading conditions of this factory, we recommended changing to oil-immersed sealed S13–M type power transformers. The factory accepted our suggestion and saved a significant amount of precious funds while economically and efficiently meeting production requirements. Oil-immersed power transformers are technically mature, naturally air-cooled, stable in quality, strong in short-circuit resistance, suitable for high humidity and high temperature environment, have strong overload capacity, long service life, and the price is about two-thirds of dry-type transformers. Therefore, unless there are fire protection requirements necessitating the use of dry-type transformers, oil-immersed sealed power transformers should be the preferred choice.